Max Laser Welding Portable Handheld

Model SN-MLWPHH-2000W

Product Description

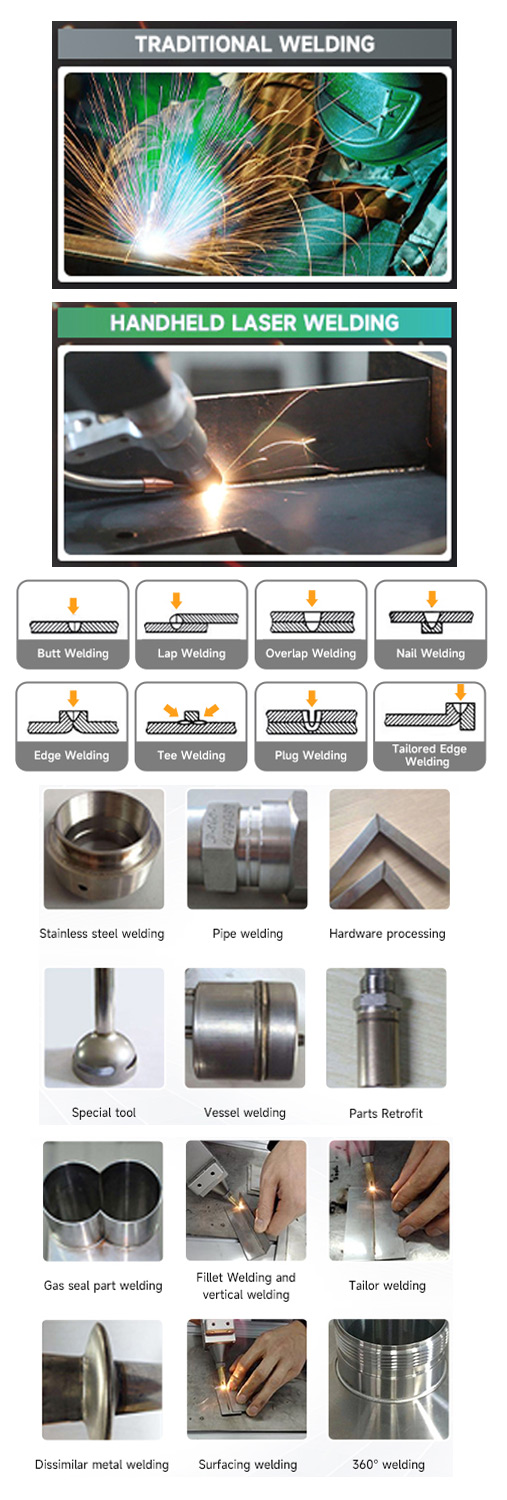

The Max laser welding Model SN-MLWPHH-2000W is a new generation of laser welding products. This model offers a highly efficient, precise, and clean method of welding, with Welding Wire Feeder and Laser Rust Remover. It is a high-end continuous welding tool.

The whole machine adopts an integrated design, which is beautiful in appearance and stable in performance. It has the characteristics of fast welding speed, high efficiency, good welding effect, less welding consumables, long life and environmental protection. It can be widely used in kitchen utensils, door and window guardrails, stair elevators, stainless steel furniture, metal sheet metal, billboards, craft gifts, Welding in auto repair, automobile manufacturing, rail transit and aerospace industries.

The hand-held laser welding machine standard wire distribution machine reduces the requirements for the clearance of the parts and further improves the welding quality. It can also be used in conjunction with a collaborative robot to fix the welding torch on the collaborative robot, reducing the operator's labor intensity and improving the welding quality of the weld.

Main Features

- Max. Output Power: 2000W

- Maximum Modulation Frequency: 100KHz

- Usage: metal welding

- Pulse Width: 5M

- Power adjustment range: 10 ~ 100%

- Fiber Core Diameter: 50 (25, 100, 200 optional)

- Aiming and positioning: red light

- Fiber length: 10m

- Work environment: 10~40C, humidity 10~85%, non-condensing

- Applicable thickness: 0.5-5mm (depends on the material)

- Wire feeder: standard, wire feeding speed 38~600mm/min

- Fiber core diameter: 50μm (35/100 optional)

- Cooling method: water cooling

s

Additional Info

- The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

- No consumables, flexible processing, low operating and maintenance costs.

- The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

- High cooling rate, which can weld fine weld structure and good joint performance.

- Simple operation,greatly reducing labor costs, fast speed and efficiency is 3-8 times that of argon arc welding.

- Indirect radiation is small;Concentrated energy and little influence of thermal deformation.

- Fine welding seam,deep molten pool,high strength;Very thin materials can be welded,such as 0.05mm stainless steel, both autogenous welding and additive welding are Ok.

- The welding head can weld the workpiece at any angle, applicable to various complex welds and various devices.

- Easy operation. No deformation of weld, stable laser output can ensure welding consistency 360C Micro Welding.

- More accurate welding position. The welding seam is smooth, the welding workpiece is not deformed, the welding is firm and the subsequent grinding process is reduced, saving time and cost.

- Laser welding depth is large, welding is strong, suitable for all kinds of complicated welding.

- It is easy to install and operate, and has high safety.

For technical information and product specifications please contact our specialists.